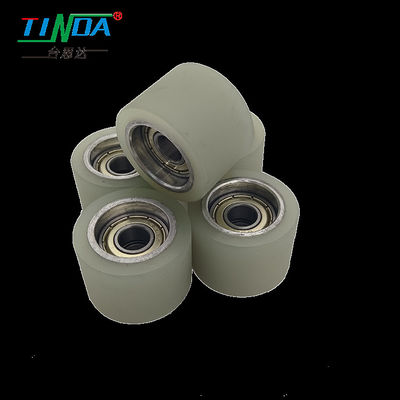

Rubber wheel Description:

One of the key features of the Rubber Feed Rollers is noise reduction. They are designed to run quietly, reducing noise pollution in the workplace. This feature makes them ideal for use in busy production facilities, where noise levels can be a challenge.

The Rubber Feed Rollers are also highly temperature-resistant. They can withstand temperatures of up to 350 Celsius, making them suitable for use in high-temperature environments. This feature ensures that the rollers remain functional and effective even in extreme conditions.

Durability is another key attribute of the Rubber Feed Rollers. They are made from high-quality rubber materials that are designed to withstand wear and tear. This makes them long-lasting and cost-effective, as they require minimal maintenance and replacement.

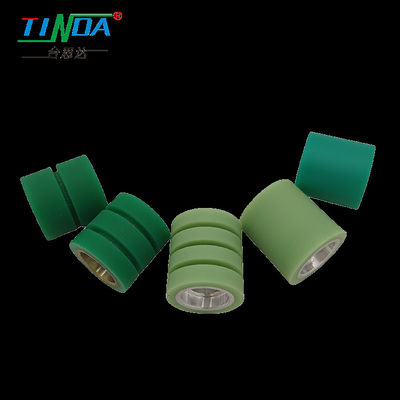

The Hot Air Wheel is one of the most popular types of Rubber Feed Rollers. It is designed to work with hot air blower machines, which are commonly used in the plastic manufacturing industry. The Hot Air Wheel is responsible for feeding the plastic materials into the machine, ensuring a smooth and efficient production process.

The Pressing Roller is another type of Rubber Feed Roller. It is designed to apply pressure to the plastic materials as they are fed into the hot air blower machine. This feature ensures that the materials are properly aligned and compressed, resulting in high-quality products.

The Holding Roller is designed to hold the plastic materials in place as they are fed into the machine. It prevents the materials from slipping or shifting, ensuring a consistent and accurate production process.

The Clip Roller is designed to clip the plastic materials onto the machine's conveyor belt. This feature ensures that the materials are properly aligned and transported through the machine, resulting in high-quality products.

The Up Roller and Down Roller work together to feed the plastic materials into the machine. The Up Roller lifts the materials up, while the Down Roller feeds them into the machine. This feature ensures a consistent and efficient production process.

In conclusion, the Rubber Feed Rollers are essential components in the hot air blower machine. They come in different types, sizes, and designs, making them suitable for different production requirements. Their noise reduction, temperature resistance, and durability make them ideal for use in high-temperature and high-volume production facilities. If you are looking for high-quality Rubber Feed Rollers for your hot air blower machine, look no further than our range of Rubberized Feeding Wheels.

Rubber wheel Features:

- Product Name: Rubberized Feed Wheels

- Features:

- Hot Air Wheel for use with hot air blower machines

- Pressing Roller for applying pressure to materials

- Holding Roller for holding materials in place

- Clip Roller for attaching materials together

- Up Roller for feeding materials from below

- Down Roller for feeding materials from above

- Durability: High

- Tolerance: High Precision, Tolerance Up To 0.02mm

- Pressure Resistance: High

- Application: ProtectiveSuit, Raincoat Manufacture

Rubber wheel Technical Parameters:

| Product Name |

Rubberized Feed Rollers, Rubber Feeding Wheels, Rubberized Feed Wheels |

| Size |

Customized |

| Shape |

Cylindrical |

| Noise Reduction |

Yes |

| Pressure Resistance |

High |

| Durability |

High |

| Temperature Resistance |

High Up 350 Celsius |

| Surface Treatment |

Smooth,Customized |

| Tolerance |

High Precision, Tolerance Up To 0.02mm |

| Application |

ProtectiveSuit, Raincoat Manufacture |

Rubber wheel Applications:

These rubber feed rollers are designed to reduce noise and provide high pressure resistance. They can be used in various applications, including ProtectiveSuit and Raincoat Manufacture. With their customized size, they can be tailored to meet your specific needs.

Whether you need a single unit or a bulk order, the minimum order quantity for TINDA-SI-1168 Rubber Feed Rollers is 1. The price is negotiable depending on the order quantity and delivery time can be advised or within 7 days. The payment terms are T/T. With a supply ability of 10000000 pcs/month, you can rest assured that you will receive your order on time.

TINDA-SI-1168 Rubber Feed Rollers are packaged in a woodbox or standard export packing to ensure safe delivery. These rollers are suitable for use in various industries and manufacturing processes, including ProtectiveSuit and Raincoat Manufacture. With their high pressure resistance and noise reduction, they are an ideal choice for those looking for a reliable and efficient product.

Rubber wheel Support and Services:

The Rubber Feed Rollers product technical support and services include:

- Expert technical assistance to help troubleshoot and resolve any issues with the feed rollers

- Product installation and setup guidance to ensure proper functioning of the rollers

- Regular maintenance and cleaning recommendations to prolong the lifespan of the rollers

- Repair services for any damages or malfunctions that may occur

- Replacement parts and accessories to keep the rollers functioning optimally

Packing and Shipping:

Product Packaging:

- The rubber feed rollers are carefully packed in sturdy cardboard boxes.

- Each box contains 10 rollers, and they are separated with protective layers to prevent damage during transport.

- The boxes are labeled with the product name, quantity, and handling instructions.

Shipping:

- We offer standard and expedited shipping options to our customers.

- Orders are processed within 24 hours and shipped within 2-3 business days.

- We use reliable shipping carriers to ensure timely delivery of our products.

- Customers can track their orders using the tracking number provided in the shipping confirmation email.

FAQ:

Q: What is the brand name of the Rubber Feed Rollers product?

A: The brand name of the Rubber Feed Rollers product is TINDA.

Q: What is the model number of the Rubber Feed Rollers product?

A: The model number of the Rubber Feed Rollers product is TINDA-SI-1168.

Q: What is the place of origin of the Rubber Feed Rollers product?

A: The place of origin of the Rubber Feed Rollers product is China.

Q: Does the Rubber Feed Rollers product come with any certification?

A: Yes, the Rubber Feed Rollers product comes with SGS certification.

Q: What is the minimum order quantity for the Rubber Feed Rollers product?

A: The minimum order quantity for the Rubber Feed Rollers product is 1.

Q: What is the price of the Rubber Feed Rollers product?

A: The price of the Rubber Feed Rollers product is negotiable.

Q: How is the Rubber Feed Rollers product packaged?

A: The Rubber Feed Rollers product is packaged in a woodbox or standard export packing.

Q: What is the delivery time for the Rubber Feed Rollers product?

A: The delivery time for the Rubber Feed Rollers product is 7 days or to be advised.

Q: What are the payment terms for the Rubber Feed Rollers product?

A: The payment terms for the Rubber Feed Rollers product are T/T.

Q: What is the supply ability of the Rubber Feed Rollers product?

A: The supply ability of the Rubber Feed Rollers product is 10000000 pcs/month.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!