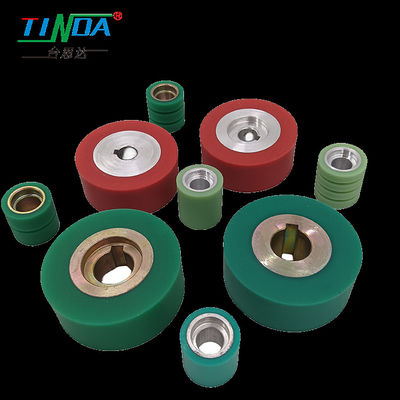

Rubber wheels Customized Description:

Our Rubber Feed Rollers are perfect for various applications, including Hot Air Wheels, Pressing Rollers, Holding Rollers, Clip Rollers, Up Rollers, and Down Rollers. Whatever your needs are, we have got you covered. The rollers are treated to ensure a smooth surface that will not damage your materials. You can use the rollers with confidence, knowing that they will deliver the expected results.

Our Rubberized Feeding Wheels are designed to withstand high temperatures of up to 350 degrees Celsius. The rollers can withstand constant use without losing their shape or structure. This makes them ideal for use in industrial settings where equipment is running continuously. You can trust our rollers to deliver the expected results without fail.

The high-quality silicone rubber material used in our rollers is known for its durability and resilience. The rollers can withstand wear and tear without losing their effectiveness. This makes them a cost-effective solution for your business needs. You will not have to replace the rollers frequently, saving you time and money in the long run.

Our Rubber Feed Rollers are made from top-quality materials that guarantee high performance and longevity. You can customize the rollers to suit your specific needs or choose from our wide range of products available in the market. The rollers are treated to ensure a smooth surface that will not damage your materials. They can withstand high temperatures of up to 350 degrees Celsius and are ideal for use in industrial settings.

Rubber wheels Features:

- Product Name:

- Rubber Feed Wheels

- Rubberized Feeding Wheels

- Hot Air Wheel

- Pressing Roller

- Holding Roller

- Clip Roller

- Up Roller

- Down Roller

- Surface Treatment:

- Application:

- Protective Suit

- Raincoat Manufacture

- Durability: High

- Wear Resistance: Yes

Rubber wheels Technical Parameters:

| Product Name |

Rubberized Feed Rollers, Rubber Feed Wheels, Sewing Rollers |

| Shape |

Cylindrical |

| Material |

Silicone Rubber, Customized |

| Surface Treatment |

Smooth, Customized |

| Size |

Customized |

| Pressure Resistance |

High |

| Tolerance |

High Precision, Tolerance Up To 0.02mm |

| Noise Reduction |

Yes |

| Wear Resistance |

Yes |

| Durability |

High |

Rubber wheels Applications:

The TINDA-SI-1168 Rubberized Feed Rollers are known for their noise reduction capabilities, making them a perfect fit for industries that require a quiet working environment. Moreover, these rubber feeding wheels are temperature resistant and can withstand high temperatures up to 350 degrees Celsius.

The Hot Air Wheel is a type of rubber feed roller that is commonly used in the printing and packaging industry. It is used to control the temperature of the printing press and maintain consistent pressure on the paper. Similarly, the Pressing Roller, Holding Roller, Clip Roller, Up Roller, and Down Roller are also types of rubber feed rollers that are used in various industries to regulate the speed and direction of the materials being fed through the machines.

The size of the rubber feed wheels can be customized as per the specific requirements of the industry. The material used to manufacture the product is silicone rubber, which can also be customized based on the industry's needs. The TINDA-SI-1168 Rubberized Feed Rollers are highly durable and can withstand wear and tear, making them a reliable and cost-effective option for industries that require efficient and consistent performance.

The supply ability of the TINDA-SI-1168 Rubberized Feed Rollers is 10000000 pcs/month, ensuring that industries can rely on a steady supply of the product. The payment terms for this product are T/T, which is widely accepted in the industry. Overall, the TINDA-SI-1168 Rubberized Feed Rollers are a reliable and efficient solution for industries that require high-quality rubber feed rollers that can withstand high temperatures and reduce noise levels.

Rubber wheels Support and Services:

The Rubber Feed Rollers product technical support and services include:

- Assistance with product installation and setup

- Troubleshooting and problem-solving for product issues

- Replacement of defective or damaged parts

- Maintenance and cleaning recommendations

- Technical training and support for customers and distributors

Rubber wheels Packing and Shipping:

Product Packaging:

The Rubber Feed Rollers are carefully packed in a durable cardboard box to ensure safe delivery. The box is labeled with the product name, quantity, and any other relevant information.

Shipping:

We offer free standard shipping for the Rubber Feed Rollers within the continental United States. Shipping time may vary depending on your location, but typically takes 3-5 business days. For international orders, shipping rates and times may vary depending on the destination country.

FAQ:

Q: What is the brand name of the rubber feed rollers?

A: The brand name is TINDA.

Q: What is the model number of the rubber feed rollers?

A: The model number is TINDA-SI-1168.

Q: Where is the rubber feed rollers manufactured?

A: The rubber feed rollers are manufactured in China.

Q: What certification does the rubber feed rollers have?

A: The rubber feed rollers have SGS certification.

Q: What is the minimum order quantity for the rubber feed rollers?

A: The minimum order quantity is 1.

Q: What is the price of the rubber feed rollers?

A: The price is negotiable.

Q: What are the packaging details for the rubber feed rollers?

A: The packaging details are woodbox or standard export packing.

Q: What is the delivery time for the rubber feed rollers?

A: The delivery time is 7 days or to be advised.

Q: What are the payment terms for the rubber feed rollers?

A: The payment terms are T/T.

Q: What is the supply ability for the rubber feed rollers?

A: The supply ability is 10000000 pcs/month.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!