Product Description:

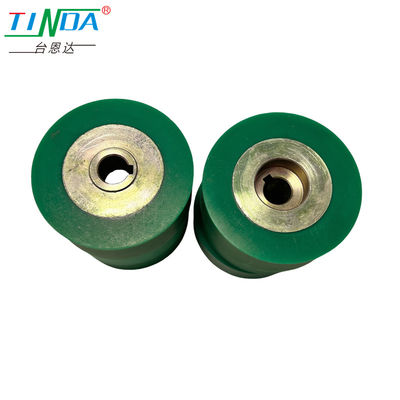

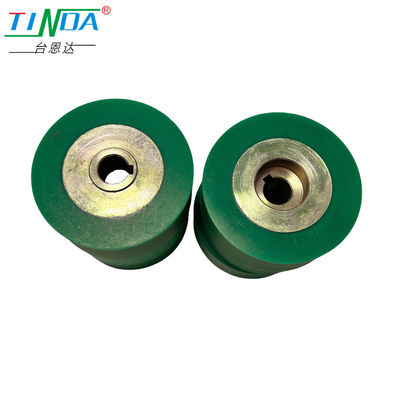

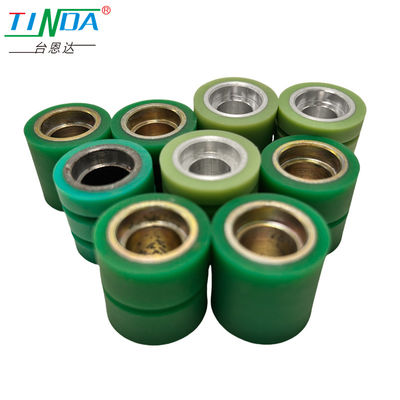

The Rubber Feed Rollers, also known as Heat Sealing Wheel, Seaming Silicone Rubber Wheel, Sealing Silicone Rubber Wheel, or Bonding Silicone Rubber Wheel, are specifically engineered to withstand tough working conditions and deliver consistent performance. Their cylindrical shape ensures efficient operation and precise feeding in seam seaming machines.

One of the key features of these Rubber Feed Rollers is their high durability. Constructed from top-grade materials, these rollers offer excellent wear resistance, ensuring a long service life and minimal maintenance requirements. Whether used in high-speed production environments or heavy-duty applications, these rollers can withstand the rigors of daily use.

Moreover, the Rubber Feed Rollers boast exceptional pressure resistance, making them suitable for handling various materials with ease. Their ability to maintain consistent pressure during operation ensures smooth feeding and reliable performance, even under challenging conditions. This pressure resistance feature enhances the overall efficiency and effectiveness of seam seaming machines.

Another standout attribute of the Rubber Feed Rollers is their high temperature resistance. These rollers can withstand elevated temperatures without compromising their performance, making them ideal for applications that involve heat sealing or bonding processes. The rubberized feed wheels are designed to maintain their integrity and functionality even in extreme heat environments, ensuring reliable operation and product quality.

When it comes to application, the Rubber Feed Rollers are specifically tailored for use in seam seaming machines. Whether you are working with fabrics, films, or other materials that require precise seaming, these rollers provide the necessary support and performance to achieve consistent results. Their cylindrical shape allows for accurate feeding and smooth operation, ensuring seamless integration into existing production processes.

In summary, our Rubber Feed Rollers are a top-of-the-line solution for industries that demand high durability, pressure resistance, and temperature resilience. With their wear resistance, high temperature resistance, and reliable performance, these rollers are the perfect choice for seam seaming applications. Trust in the quality and efficiency of our Rubber Feed Rollers to enhance your production processes and deliver superior results.

Features:

- Product Name: Rubber Feed Rollers

- Durability: High

- Tolerance: High Precision, Tolerance Up To 0.02mm

- Temperature Resistance: High Up to 350 Celsius

- Noise Reduction: Yes

- Application: Seam Seaming Machine

- Features:

- Wear-resistant rubber material

- Effective as both feed roller and guide roller

- High precision for accurate feeding

- Temperature resistant for use in high-heat environments

- Noise reduction properties for quieter operation

Technical Parameters:

| Attribute |

Value |

| Material |

Silicone Rubber, Customized |

| Shape |

Cylindrical |

| Product Name |

Heat Sealing Wheel, Seaming Silicone Rubber Wheel, Sealing Silicone Rubber Wheel, Bonding Silicone Rubber Wheel |

| Noise Reduction |

Yes |

| Pressure Resistance |

High |

| Surface Treatment |

Smooth, Customized |

| Durability |

High |

| Hot air Temperature |

High Up to 750 Celsius |

| Tolerance |

High Precision, Tolerance Up To 0.02mm |

| Application |

Seam Seaming Machine |

Applications:

TINDA Rubber Feed Rollers, also known as Rubberized Feeding Wheels, are versatile and high-quality products suitable for various applications. These rollers are manufactured by TINDA, a reputable brand known for its reliability and innovation in the industry. The model number for these rollers is TINDA-SI-1168, and they are produced in China, ensuring high standards of quality and production.

These Rubber Feed Rollers are certified by SGS, guaranteeing their quality and compliance with international standards. They are designed to provide excellent wear resistance, making them ideal for demanding industrial environments where durability is critical. The rollers are made from high-quality silicone rubber, with the option for customization to suit specific requirements.

With a high temperature resistance of up to 350 degrees Celsius, these rollers are suitable for applications where heat is a factor. The hot air temperature resistance of up to 750 degrees Celsius makes them suitable for even more extreme conditions. Additionally, these rollers feature noise reduction properties, ensuring a quieter working environment.

Whether used in manufacturing, printing, packaging, or other industries, TINDA Rubber Feed Rollers offer reliable performance and longevity. The minimum order quantity is 1, and pricing is negotiable, providing flexibility for different business needs. Packaging options include woodbox or standard export packing, ensuring secure delivery.

Orders are processed quickly, with a delivery time of 7 days or as advised. Payment terms are convenient, with T/T accepted. TINDA has a supply ability of 10,000,000 pcs per month, ensuring that customers' needs can be met promptly and efficiently.

In summary, TINDA Rubber Feed Rollers are the ideal choice for businesses seeking high-quality, wear-resistant rollers for their operations. Their durability, temperature resistance, noise reduction, and customizable options make them a versatile and reliable solution for various industrial applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!