Product Description:

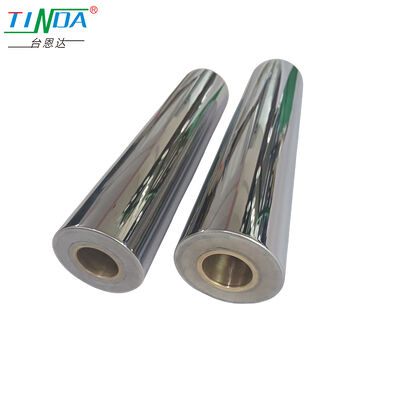

The Industrial Metal Roller is a high-precision component designed to meet the rigorous demands of the aerospace industry. Engineered with an exceptional tolerance of 0.02mm, this roller ensures unparalleled accuracy and performance in critical applications where precision is non-negotiable. Manufactured under the production name Super Mirrored Chrome Steel, the roller exhibits a superior finish that not only enhances its aesthetic appeal but also contributes to its outstanding durability and functionality.

Constructed from a range of premium materials including #45 Steel, Aluminum, and various grades of stainless steel such as 304L, 316L, 2205, and 904L, the Industrial Metal Roller offers versatility and adaptability to different operational environments. The use of stainless steel rollers in its design ensures excellent resistance to corrosion and wear, which is vital for maintaining performance over prolonged periods, especially in aerospace applications where reliability is paramount.

One of the standout features of this product is the incorporation of hard anodic oxidation on the steel roller surfaces. This advanced surface treatment significantly enhances hardness and surface endurance, making the roller highly resistant to abrasion and surface degradation. The hard anodic oxidation process also contributes to maintaining a stable vibration level, which is remarkably low in this product. Low vibration levels are critical in aerospace components to reduce noise, wear, and operational inefficiencies, thereby extending the lifespan of the equipment in which the rollers are installed.

The Industrial Metal Roller’s chrome roller finish is another key attribute that underpins its performance excellence. The chrome plating not only provides a mirror-like sheen that aligns with the Super Mirrored Chrome Steel production standard but also offers additional protection against corrosion and mechanical damage. This chrome roller surface facilitates smooth operation and reduces friction, which is essential for maintaining consistent mechanical performance in high-speed or high-load aerospace machinery.

Designed specifically for the aerospace industry, this roller meets stringent quality and performance standards. The combination of low vibration, precise tolerance, and superior material selection makes it ideally suited for use in aircraft manufacturing, maintenance, and other aerospace-related applications. Its robust construction ensures it can withstand extreme environmental conditions and operational stresses typical in aerospace settings.

Moreover, the Industrial Metal Roller’s diverse material options allow customization based on specific application requirements. Whether the need is for lightweight aluminum rollers or highly corrosion-resistant stainless steel rollers, this product can be tailored accordingly. The inclusion of various stainless steel grades like 304L, 316L, 2205, and 904L ensures compatibility with different chemical and mechanical conditions, further broadening its application scope within the aerospace sector.

In summary, the Industrial Metal Roller represents the pinnacle of precision engineering and material science. Its hard anodic oxidation steel roller surfaces, chrome roller finish, and stainless steel roller options combine to deliver a product that is both durable and highly efficient. With a tolerance of just 0.02mm and a low vibration level, it is perfectly suited for the demanding environments of the aerospace industry, providing reliable, long-lasting performance essential for modern aerospace technology.

Features:

- Product Name: Industrial Metal Roller

- Shaping Mode: Forging Mould or Customized

- Surface Treatments: Chrome-plated

- Shape: Cylindrical

- Material Options: Metal, #45 Steel, Aluminum, Stainless Steel Roller

- Available Stainless Steel Types: 304L steel roller, 316L steel roller, 2205, 904L

- Tolerance: 0.02mm

- Additional Surface Option: Powder coated steel roller

Technical Parameters:

| Tolerance |

0.02mm |

| Application |

Aerospace Industry |

| Shaping Mode |

Forging Mould Or Customized |

| Production Name |

Super Mirrored Chrome Steel |

| Material |

Metal ; #45 Steel ; Aluminum, Stainless Steel Roller; Stainless Steel 304L, 316L, 2205, 904L |

| Surface Treatments |

Chrome-plated |

| Vibration Level |

Low |

| Shape |

Cylindrical |

Applications:

The TINDA-Steel-868 Industrial Metal Roller, manufactured by the renowned brand TINDA in China, is a versatile and high-performance product designed to meet the demanding needs of various industrial applications. Certified by SGS, this metal roller is crafted from premium materials including #45 Steel, Aluminum, and stainless steel varieties such as 304L, 316L, 2205, and 904L, ensuring exceptional durability and resistance to wear and corrosion. Its cylindrical shape and forging mould or customized shaping mode further enhance its precision and reliability in operation.

One of the hallmark features of the TINDA-Steel-868 is its low vibration level, making it ideal for applications requiring smooth and stable performance. The roller is also available with specialized Teflon treatment, which significantly reduces friction and extends the lifespan of the roller in high-demand environments. This makes it particularly suitable for industries where consistent, low-friction rolling is critical.

The Industrial Metal Roller finds extensive application in the aerospace industry, where precision and material integrity are paramount. The 316L steel roller variant is especially favored in aerospace manufacturing due to its excellent corrosion resistance and strength, which are crucial for components exposed to harsh conditions. Additionally, the Aluminum roller option provides a lightweight alternative without sacrificing strength, making it suitable for aerospace parts that require both durability and weight efficiency.

Beyond aerospace, these rollers are used in various heavy machinery and manufacturing processes where metal rollers are essential for conveying, shaping, or processing materials. The ability to customize the roller according to specific forging moulds allows TINDA to cater to unique industrial requirements, ensuring optimal performance in diverse operational scenarios.

With a supply ability of 10,000,000 pieces per month and flexible payment terms such as T/T, TINDA ensures timely delivery, typically within 7 days or as advised. The product is securely packaged in wood boxes or standard export packing to protect it during transit. The minimum order quantity of just one piece makes it accessible for both large-scale industrial buyers and smaller enterprises seeking high-quality metal rollers for their production lines.

In summary, the TINDA-Steel-868 Industrial Metal Roller is an indispensable component in aerospace and other high-precision industries, offering superior material options such as 316L steel roller, Aluminum roller, and advanced surface treatments like Teflon to meet rigorous operational demands.

Customization:

Our Industrial Metal Roller, model TINDA-Steel-868, by TINDA, offers exceptional customization services to meet your specific needs. Manufactured in CHINA and SGS certified, this product ensures high quality and reliability for your industrial applications.

We provide a minimum order quantity of 1 piece, with pricing available through negotiation to suit your project requirements. Each roller is carefully packaged in a woodbox or standard export packing to ensure safe delivery.

With a supply ability of 10,000,000 pcs per month and a typical delivery time of 7 days or as advised, we guarantee prompt fulfillment of your orders. Payment terms are flexible, primarily through T/T.

The shaping mode can be forging mould or customized according to your specifications, offering a cylindrical shape with chrome-plated surface treatments for enhanced durability and corrosion resistance. Our rollers feature low vibration levels, ensuring smooth operation in your machinery.

Material options include metal varieties such as #45 steel, aluminum, stainless steel rollers, and premium grades like stainless steel 304L, 316L, 2205, and 904L. We specialize in producing high-quality mirro roller finishes, dark brown steel rollers, and 316L steel rollers to match diverse industrial needs.

Choose TINDA's Industrial Metal Roller customization services for tailored solutions that deliver performance, longevity, and precision in every piece.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!