Product Description:

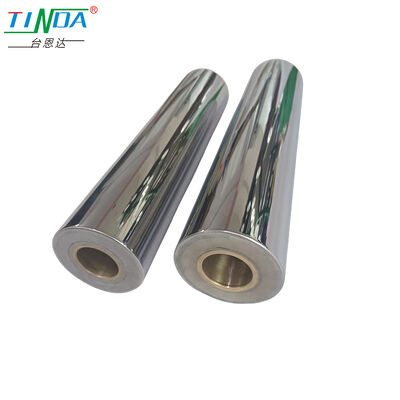

The Industrial Metal Roller is a precision-engineered component designed to meet the highest standards of quality and performance in various industrial applications. Crafted with meticulous attention to detail, this roller boasts an exceptional tolerance of 0.02mm, ensuring unparalleled accuracy and consistency in operation. Its cylindrical shape allows for smooth rotation and efficient load distribution, making it an ideal choice for industries requiring reliable and durable rollers.

This roller is produced under the renowned name of Super Mirrored Chrome Steel, reflecting its superior surface finish and exceptional durability. The manufacturing process involves advanced techniques that result in a mirror-like surface, enhancing not only the aesthetic appeal but also the functional efficiency of the roller. The mirror finish minimizes friction and wear, contributing to extended service life and optimal performance in demanding environments.

Material selection for the Industrial Metal Roller is versatile and robust, catering to a wide range of industrial needs. It is available in high-quality metal variants including #45 steel, aluminum, and various grades of stainless steel such as 304L, 316L, 2205, and 904L. The #45 steel roller variant is particularly notable for its excellent mechanical properties, including high strength and good wear resistance, making it suitable for heavy-duty applications where durability is critical.

Surface treatment plays a crucial role in enhancing the roller's performance, and this product features a chrome-plated finish that significantly improves its hardness and corrosion resistance. The anodizing treatment HV300 further elevates the roller's surface characteristics by providing a hard, wear-resistant layer that protects against abrasion and environmental factors. This combination of chrome plating and anodizing treatment ensures that the steel roller maintains its integrity and smooth operation even under harsh conditions.

One of the standout features of this Industrial Metal Roller is the mirro roller finish, which offers a highly polished, reflective surface that reduces friction and heat generation during use. This mirror finish not only improves mechanical efficiency but also facilitates easier cleaning and maintenance, making it an excellent choice for applications where hygiene and smooth operation are paramount.

The steel roller anodizing treatment HV300 is a testament to the advanced surface engineering applied to this product. This treatment enhances the hardness and durability of the roller surface, providing resistance to wear and extending the lifespan of the component. It also contributes to improved corrosion resistance, making the roller suitable for use in environments exposed to moisture and chemicals.

In summary, the Industrial Metal Roller combines precision engineering with high-quality materials and advanced surface treatments to deliver a product that excels in performance, durability, and reliability. Its tolerance of 0.02mm, cylindrical shape, and production under the Super Mirrored Chrome Steel name make it a top choice for industries requiring superior rollers. Whether you require a #45 steel roller for heavy-duty tasks or a stainless steel variant for corrosion resistance, this product offers versatility and excellence. The mirror roller finish and steel roller anodizing treatment HV300 further enhance its capabilities, ensuring long-lasting and efficient operation across various industrial applications.

Features:

- Product Name: Industrial Metal Roller

- Material: Metal including #45 Steel, Aluminum, Stainless Steel Roller options such as 304L, 316L, 2205, and 904L

- Tolerance: Precise tolerance of 0.02mm

- Shaping Mode: Forging mould or customized shaping available

- Production Name: Super Mirrored Chrome Steel finish

- Shape: Cylindrical design for optimal performance

- High-quality Steel roller with various steel grades

- Durable 304L steel roller option for corrosion resistance

- Lightweight and strong Aluminum roller available

Technical Parameters:

| Shape | Cylindrical |

| Material | Metal; #45 Steel; Aluminum; Stainless Steel Roller; Stainless Steel 304L, 316L, 2205, 904L |

| Application | Aerospace Industry |

| Shaping Mode | Forging Mould Or Customized |

| Tolerance | 0.02mm |

| Vibration Level | Low |

| Surface Treatments | Chrome-plated |

| Production Name | Super Mirrored Chrome Steel |

Applications:

The TINDA Industrial Metal Roller, model number TINDA-Steel-868, is a highly versatile and precision-engineered product originating from China. Certified by SGS, this roller is designed to meet the rigorous demands of various industrial applications, particularly in the aerospace industry. With a tolerance of just 0.02mm and a low vibration level, it ensures exceptional performance and reliability in critical environments.

This product is available in multiple material options including #45 Steel, Aluminum, and a range of stainless steels such as 304L, 316L, 2205, and the super stainless steel 904L roller. The aluminum roller variant benefits from anodizing treatment HV300, which significantly enhances durability and corrosion resistance, making it ideal for applications requiring lightweight yet robust components. Meanwhile, the steel roller options, including chrome-plated finishes, provide superior hardness and wear resistance essential for heavy-duty industrial use.

The TINDA-Steel-868 is particularly well-suited for aerospace applications where precision, durability, and material quality are paramount. Its chrome-plated surface treatment offers excellent protection against wear and corrosion, ensuring long service life even under harsh operating conditions. The super stainless steel 904L roller variant delivers outstanding chemical and mechanical resistance, making it perfect for environments exposed to aggressive substances and extreme temperatures.

Beyond aerospace, these industrial metal rollers can be applied in manufacturing lines, conveyor systems, and other machinery requiring reliable rolling components with minimal vibration. The product’s packaging options, including woodbox or standard export packing, guarantee safe transport and delivery within approximately 7 days or as advised. With a supply capacity of up to 10,000,000 pieces per month and flexible payment terms via T/T, TINDA offers a dependable sourcing solution tailored to various industrial needs.

Whether customers require a single unit or bulk orders, pricing is open for negotiation to accommodate different project scales. Overall, the TINDA-Steel-868 industrial metal roller stands out as a premium choice for applications demanding precision, durability, and advanced material properties such as the anodized aluminum roller, steel roller with HV300 treatment, and the super stainless steel 904L roller.

Customization:

Introducing the TINDA Industrial Metal Roller, model TINDA-Steel-868, proudly manufactured in CHINA with SGS certification ensuring top-quality standards. Our Metal roller is designed with precision using premium materials including #45 Steel, Aluminum, and various grades of Stainless Steel such as 304L, 316L, 2205, and 904L, making it ideal for demanding applications in the aerospace industry.

The 316L steel roller variant offers exceptional corrosion resistance and durability, perfect for environments requiring low vibration levels and reliable performance. Each cylindrical Metal roller undergoes advanced chrome-plated surface treatments to enhance wear resistance and extend service life.

We provide flexible customization services with a minimum order quantity of just 1 piece. Packaging is handled carefully using woodbox or standard export packing to ensure safe delivery. Our supply ability is robust, with up to 10,000,000 pcs per month, and delivery time typically within 7 days or as advised.

Pricing is negotiable to meet your specific project needs, and payment terms are convenient via T/T. Trust TINDA for high-quality Metal roller solutions tailored to your industrial requirements, backed by expert service and reliable supply chain support.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!